neues Rezept 🙂

2 Bleche, 500g Mehle

– Buchweizenmehl 180g

– Reisvolkornmehl 180g

– Maisstärke 100g

– Braunhirsemehl 40g

– Wasser 360ml

– 1Tüte Weinstein-Backpulver

– eine Gute Priese gemahlene Flohsamenschalen (Pulver)

Umluft 190°C

auf unterster Schiene 15-20min

Author: Stefan

funny plastic material…

did you know there is a plasict material that melts at about 60°C ?

the official name / main ingredient is

Polycaprolacton (PCL) (wikipedia: de en)

product names i found:

- Polymorph

- InstaMorph

- Plaast Kunststoff (de shop) (i used this one)

- Gorilla Plastic (link:wayback)

the challeng is to get a good water bath in the right temperature.

so for this i reused my HotPlate SMD soldering hardware.

created a profile that just heats to 60°C and waits…

i will add some pictures and experiment results here in some days 😉

Arduino Light-Barrier with TSOP4438

you just want to build a Light-Barrier (DE: Lichtschranke) ?

for example to measure speed? Or Count goals on a Table-Top-Football?

then you are at the right place.

We use a TSOP4438 as Receiver and some 5mm IR-LED as Sender.

the code

IR_TSOP4438_light_barrier_withDebounce/ir_light_barrier.ino

// based on

// Example of modulating a 38 KHz carrier frequency at 500 Hz with a variable duty cycle

// Author: Nick Gammon

// Date: 24 September 2012

// https://forum.arduino.cc/t/how-to-create-a-38-khz-pulse-with-arduino-using-timer-or-pwm/100217/44

// tweaked for TSOP4438

// https://www.vishay.com/docs/82459/tsop48.pdf

// find max burst length and min gap times:

//

// Minimum burst length 10 cycles/burst

// After each burst of length 10 to 40 cycles

// a minimum gap time is required of ≥ 10 cycles

// Maximum number of continuous short bursts/second: 1500

//

// translates to:

// 38kHz = 26,3 us / Pulse → *10= 263us

// max burst length: <= 1052us (26,3*40)

// min gap length: >= 263us (26,3*10)

// total cycle time of (1052+263=) 1315us

// that violates the max bursts/second (666us/burst)

//

// on option is to optimize for the most bursts/second:

// so we use the min gap time as given and use the rest of the available time.

// 666us - 263us = 403 us burst length

// hopefully this way the AGC does not filter our stream...

// we now have to fit this to the best available prescaler / counter values:

// 672us fits good (this way we have less than the 1500 burst)

// this translates to 42 counts a' (0,0625us*256=) 16us

// so we use a gap length of 16us*17 = 272us

// this gives us a burst length of 16us*(42-17)= 400us

//

// second option is to optimize for the longest burst length and have less bursts/second.

// here we will use a in-between leaning towards longer bursts:

// 0,0625us*256=16us

// 16us*50counts = 800us = 0,80ms = 1250,00Hz = 1250bursts/s

// 16us*80counts = 1280us = 1,28ms = 781,25Hz = 781,25bursts/s

// gap length: 16us*17 = 272us

// burst length: 16us*(80-17) = 1008us

// http://www.gammon.com.au/forum/?id=11504

// Timer 1

// OC1A: D9

// OC1B: D10

const byte LED = 9;

// Timer 2 (8bit)

// OC2A: D11

// OC2B: D3

// Clock frequency divided by 38 kHz frequency desired

const long timer1_OCR1A_Setting = F_CPU / 38000L;

// (16000000 / 38000) = 421,05

// this only works on Timer 1 - as it is a 16bit timer.

// ------------------------------------------

// in-between - leaning for longer bursts

// target counts:

// CPU 16MHz (0,0625us)

// prescaler 256

// target 781kHz (1280us = 1,28ms)

const long timer2_top = (F_CPU / 256L) / 781L;

// (16000000 / 256) / 781 = 80

// calculate on / off ratio (toggle point)

const long timer2_compare = timer2_top * 1008L / 1280L;

// 80 * 1008 / 1280 = 80 - 17 = 63

volatile bool sender_active = false;

ISR (TIMER2_COMPA_vect) {

// used to combine the two timers...

if (sender_active == false) {

// enable timer1 output

TCCR1A |= bit(COM1A0) ; // Toggle OC1A on Compare Match

// digitalWrite (LED_BUILTIN, HIGH);

sender_active = true;

} else {

sender_active = false;

// disable timer1 output

TCCR1A &= ~bit(COM1A0) ; // DO NOT Toggle OC1A on Compare Match

digitalWrite (LED, LOW); // ensure off

// digitalWrite (LED_BUILTIN, LOW);

}

}

void lightBarrierSender_setup() {

pinMode(LED, OUTPUT);

digitalWrite(LED, LOW);

pinMode(LED_BUILTIN, OUTPUT);

digitalWrite(LED_BUILTIN, LOW);

// set up Timer 1 - gives us 38.095 KHz

TCCR1A = bit (COM1A0); // toggle OC1A on compare

TCCR1B = _BV(WGM12) | _BV (CS10); // CTC to OCR1A, No prescaler

OCR1A = (16000000L / 38000L / 2) - 1; // zero relative

// setup Timer 2

TCCR2A = 0;

TCCR2B = 0;

// toggle OC2A on compare

// TCCR2A |= bit(COM2A0);

// fast pwm to OCR2A

TCCR2A |= bit(WGM21) | bit(WGM20);

TCCR2B |= bit(WGM22);

// prescaler 1024

// TCCR2B |= bit(CS22) | bit(CS21) | bit(CS20);

// prescaler 265

TCCR2B |= bit(CS22) | bit(CS21);

// top

OCR2A = timer2_top - 1; // zero relative

// switch point

OCR2B = timer2_compare - 1; // zero relative

// enable interrupts

TIMSK2 = bit(OCIE2A);

// TIMSK2 = bit(OCIE2B) | bit(OCIE2A);

}

/IR_TSOP4438_light_barrier_withDebounce/IR_TSOP4438_light_barrier_withDebounce.ino

// simple light barrier test

unsigned long debounceDuration = 10;

const byte beam1Pin = 2;

bool beam1State = LOW;

bool beam1StateLast = LOW;

unsigned long beam1Timestamp = 0;

const byte beam2Pin = 3;

bool beam2State = LOW;

bool beam2StateLast = LOW;

unsigned long beam2Timestamp = 0;

void setup(){

Serial.begin(115200);

Serial.println("IR_TSOP4438_light_barrier");

Serial.println("setup...");

pinMode(beam1Pin, INPUT);

pinMode(beam2Pin, INPUT);

lightBarrierSender_setup();

Serial.println("running.");

}

void loop() {

beam1_check();

beam2_check();

}

void beam1_check() {

bool beam1Current = digitalRead(beam1Pin);

if(beam1Current != beam1StateLast) {

beam1Timestamp = millis();

}

if ((millis() - beam1Timestamp) > debounceDuration) {

// egal welcher wert - dieser ist länger als debounceDuration da!

// check for state change

if(beam1Current != beam1State) {

beam1State = beam1Current;

if(beam1State) {

Serial.println("beam1 brock...");

}

}

}

beam1StateLast = beam1Current;

}

void beam2_check() {

bool beam2Current = digitalRead(beam2Pin);

if(beam2Current != beam2StateLast) {

beam2Timestamp = millis();

}

if ((millis() - beam2Timestamp) > debounceDuration) {

// egal welcher wert - dieser ist länger als debounceDuration da!

// check for state change

if(beam2Current != beam2State) {

beam2State = beam2Current;

if(beam2State) {

Serial.println("beam2 brock...");

}

}

}

beam2StateLast = beam2Current;

}or just download this arduino sketchbook:

deep dive into the details

To get the TSOP4438 to work we need to send a 38kHz Modulated Signal from the LED. the catch: the receiver is designed to ignore CONTINUOUS signals – that is the way to also reject all the Disturbance from surrounding things like Fluorescent Lamps or other things…

therefore we need to modulate again the 38kHz signal:

so that there are times the signal is send and breaks where the beam is off. The timing requirements for this Pattern are described in the Datasheet :

Minimum burst length 10 cycles/burst

After each burst of length 10 to 40 cycles

a minimum gap time is required of ≥ 10 cycles

For bursts greater than 40 cycles

a minimum gap time in the data stream is needed of > 10 x burst length

Maximum number of continuous short bursts/second 1500To Be continued…

Research:

- https://www.vishay.com/docs/82459/tsop48.pdf#page=6&zoom=250,-155,381

- https://forum.arduino.cc/t/how-to-create-a-38-khz-pulse-with-arduino-using-timer-or-pwm/100217/12

- https://forum.arduino.cc/t/how-to-create-a-38-khz-pulse-with-arduino-using-timer-or-pwm/100217/64

- http://www.gammon.com.au/forum/?id=11504&reply=6#reply6

- http://www.gammon.com.au/forum/bbshowpost.php?id=11504&page=2

- http://www.gammon.com.au/images/Arduino/Timer_2.png

- http://www.gammon.com.au/images/Arduino/Timer_1.png

- https://arduino.stackexchange.com/questions/31187/irremote-send-and-receive-same-arduino

- http://www.righto.com/2010/03/detecting-ir-beam-break-with-arduino-ir.html?showComment=1447463463512#c570784324410264988

Vegane Elisenlebkuchen / Nusstaler

Diesmal war die Challenge *Basische* Leckereien für mich zu Zaubern.

es geht in Richtung Elisenlebkuchen – ich würde es eher als Nusstaler benennen.

Zutaten

die meisten Zutaten habe ich von Rapunzel verwendet.

Zutaten

- 50g Datteln

- 90g Rosinen

- 120g Haselnüsse

- 140g Mandeln

- 60g Cachewkerne

- ca 7g Lebkuchengewürz

- ca 4g Ceylon Zimt

- ein bisschen geriebene und getrocknete Orangenschale

- eine Halbe Zitrone (inkl. Schale!!)

- einen kleinen Schluck Wasser

Zubereitumg

- Datteln kleiner schneiden

- Dateln & Rosinen mit sehr heisem Wasser einweichen

- Nüsse alle zussammen mischen

- hälfte davon in kleinen portionen mit einem Hexler sehr fein mahlen

- zweite hälfte gröber hexeln

- zur Seite stellen

- Datteln & Rosinen Gewürze & die (zerteilte) Zitrone mit einem kleinen Teil des Einweich-Wassers sehr fein Hexeln

- dies gibt eine feine creme

- diese creme mit der Nussmischung verrühren / kneten

- wenn gleichmäßig verknettet für mehrere Stunden Kühl-Stellen

- Ofen Vorheizen: Umluft 140°C

- dann den Teig in kleine Haufen aufteilen

- diese dann zwischen den Handflächen rollen – dadurch entstehen Kugeln die eine glatte Oberfläche haben

- jeweils die Kugel mit dem Handballen flachdrücken (ca 1cm Höhe)

- dann ab in den Backofen (140°C Umluft) – ca 15-20min – leichte bräune = fertig 🙂

- kurz auskühlen lassen

Frisch schmecken sie mir am besten 🙂

ich finde sie sehr gelungen – das nächste mal etwas mehr zitrone und mehr Zimt –

das macht es Frischer und Würziger.. (das Lebkuchengewürz hatte eine starke Nelke-Note..)

Das Konzept des Zweiteiligen Hexelns wie ich es mir beim letzten mal ausgemahlt habe ist aufgegangen.

Gerne wieder 🙂

actual soldering :-)

this morning i did a last test-run with the tweaked Felder ISO-Cream profile:

yeah… at the top i thought it is in the cooling step already and opened the window – with ~3°C cold air from outside it dropped fast..

then i found it is in the middle of the reflow – sorry… and closed the window again – until it really switched to cooling..

the old left-over pcb i use for these is done now.. i comes from my LEDBoard_4x4_16bit project – and if i remember correctly i backed it with the assembled board in the oven multiple times back then..

now grilled it again ~4-7 times. it smells very bad – is super dark discolored.. i think that is ok with about ~12 times solder cycles..

and then started to assemble a simple board to really test the profile 🙂

then reflowed:

i added a paper-lid to have stable air inside..

reflow was successful 🙂

my profile is just a little bit to long for my right angle touch switches:

they melted away 🙁 – lesson learned – have a look in the datasheet and you know that they are very heat sensitive!

in general i have the feeling that my heating elements get a little bit to hot – the pcb also slightly discolored at on place…

so will keep an eye on this and improve it..

Open Points

- add housing

- i would like to have class at the top for a good view what is happening inside..

- metal frame for heating-elements

- quite 5V fan with PWM control for cooling

- maybe quiet! Silent Wings 3 PWM 120 mm

- or similar NOCTUA NF-F12 5V PWM

- add second temperature sensor

- spring thing to hold board down

- way to fix sensor position on board

- more heating elements for bigger working area

- switchable configuration for long or more square pcbs?!

- bigger / second power supply ?! (~750W)

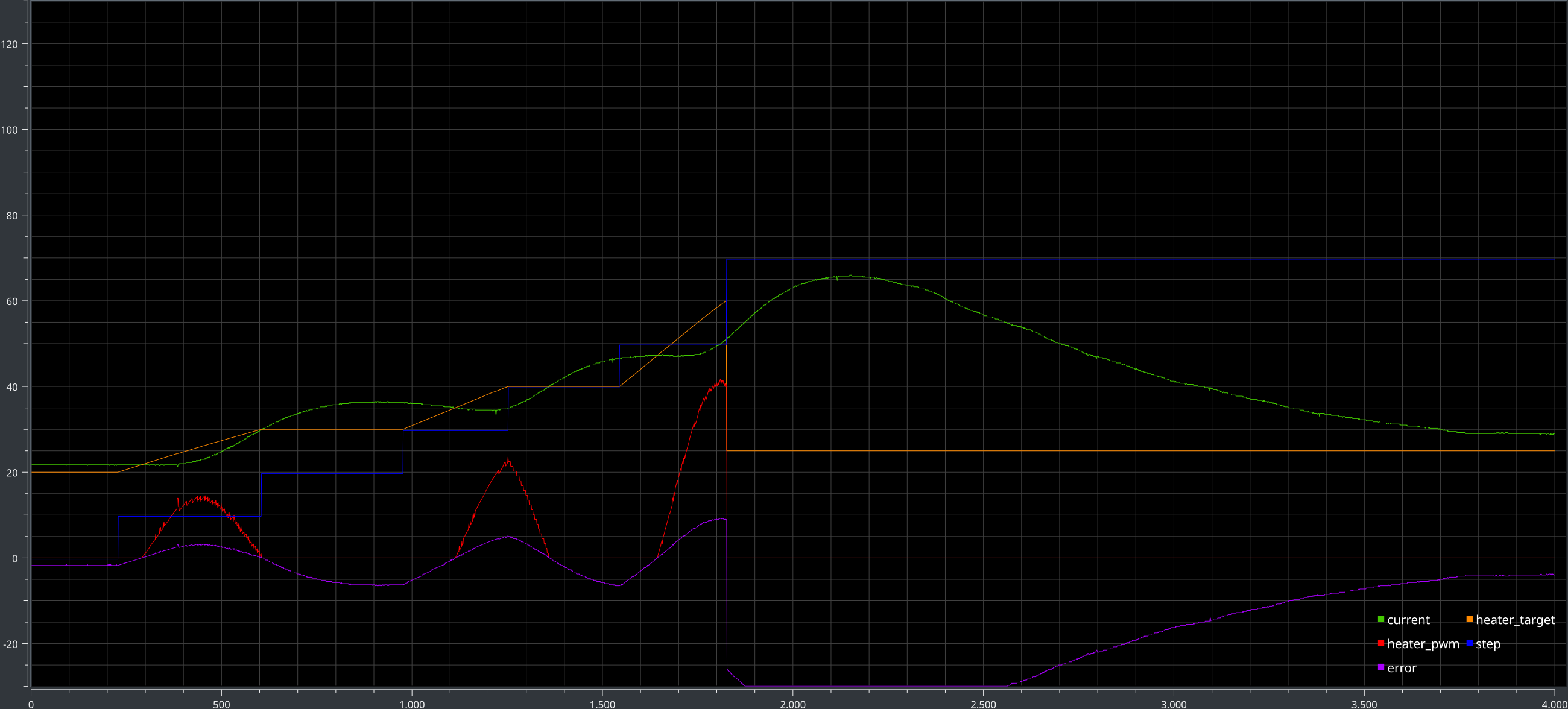

Testing & Tuning the PID

for tuning i followed more or less the tutorial PID Without a PhD

from Tim Wescott

and the tutorial and video from PID Explained Team.

first i just checked with low temperatures of 20..40°C

as i went on and tested up to 260°C i noticed that the current did decrease. and the temperature did not increase any more.

i could see this in my graph as the heating got slower and slower with the rising temperature… (also the pid already saturated at the output..)

so i measured the resistance during the cool down of the heating elements to get some insights:

(4x in series → 48V/4=~12V/Module)

| Temperature (°C) | Resistance (Ohm) | Current (A) | Power @48V (W) |

|---|---|---|---|

| 255 | 40 | 1,19 | 57 |

| 250 | 39 | 1,21 | 58 |

| 240 | 38 | 1,23 | 59 |

| 230 | 36 | 1,26 | 60,5 |

| 220 | 38 | 1,26 | 60,3 |

| 200 | 34 | 1,35 | 64,8 |

| 100 | 26 | 1,8 | 88,6 |

| 80 | 24 | 2 | 96 |

| 60 | 22 | 2,18 | 104 |

| 40 | 20,9 | 2,3 | 110 |

| 25 | 19,5 | 2,46 | 118 |

result: the ~57W is not enough to get to more than 255°C…

i rearranged the Modules into 3-in-series connection.

this means ~16V/Module – and tested again:

| Temperature (°C) | Resistance (Ohm) | Current (A) | Power @48V (W) |

|---|---|---|---|

| 255 | 27,5 | 1,45 | 70 |

| 250 | 27,0 | 1,5 | 72 |

| 240 | 26,6 | 1,6 | 77 |

| 230 | 25,6 | 1,67 | 80 |

| 220 | 25,3 | 1,7 | 82 |

| 200 | 24,1 | 1,8 | 86 |

| 100 | 18,8 | 2,1 | 100 |

| 80 | 17,5 | 2,7 | 130 |

| 60 | 16,7 | ||

| 40 | 15,6 | ||

| 25 | 14,3 |

with this i found that i can go above 255°C.

i then tested the profile for the Felder ISO-Cream “Clear” and found that in the reflow stage the heat-up is a little to slow:

in the *my setup* picture is a temporary cardboard thing with a 80mm 12V fan (connected to 5V) to cool down faster between tests.

for the final setup i think i will buy 1 or two 5V and PWM capable fans….

and also exchange the *chamotte* ston with some metal frame.

this way i also can cool the bottom side..

so i again switch the configuration –

now i have a 2-in-series config: 24V/Module

CURRENTLY THIS TABLE IS ONLY CALCULATED VALUES!!

| Temperature (°C) | Resistance (Ohm) | Current (A) | Power @48V (W) |

|---|---|---|---|

| 255 | 20 | 2,4 | 115 |

| 250 | 19,5 | 2,46 | 118 |

| 240 | 19 | 2,52 | 121 |

| 230 | 18 | 2,67 | 128 |

| 220 | 17,5 | 2,74 | 132 |

| 200 | 17 | 2,82 | 135 |

| 100 | 13 | 3,69 | 177 |

| 80 | 12 | 4 | 192 |

| 60 | 11 | 4,36 | 209 |

| 40 | 10,45 | 4,59 | 220 |

| 25 | 9,75 | 4,92 | 236 |

Temperature / Resistance – 2 Modules in Series – 24V/Module

i also tested this with the Felder profile:

this time the heat-up is fast enough! 🙂

the nice and working pid tuning i had for the 4-in-series arrangement is now out of tune…

so i will have to re-tune it to get less overshoot / swing.

while having a break i thought about the maximal power in this configuration –

and found that this way i only be able to power 2×2 modules with my 250W power supply.

for now i leave it this way. in the long run i hope with the other frame concept i get more heat to the pcb and less into the stone and this way be able to use the 3S config.

Tuning

after a day of mostly waiting til the system cooled down again

– one test cycle <=60°C needs 400s → 6:40min –

i just rebuild my hw mounting setup.

new setup

details of mounting

this way i can warm up quicker and cool down much quicker as i do not store heat in the stone. – at least that is what i hope..

hmmm – does not seem to change much..

i then tested the actual Felder Profile:

seems i have a working profile.

i will add a little more time for the prepare phase. so the pcb is really fully at the 50°C. at the top i have a little bit of a mis-match –

i saw on my temp sensor directly connected to the heating elements at the top ~265°C – so that is hot…

the pcb seems to increase its temperature resistance at higher temperatures… at the peak i have 230°C to 245°C error. and to the heating this results in ~35°C difference…

i will report when i solder the first real board. 😉

progress..

there was a response to my request in the forum..

and hw & sw basics done..

the idea & planing

the idea came from this Applied Science Video:

Electroluminescent paint and multi-channel control circuit

21 Nov 2018 starting at 11:25

there is a link to amazon for a element – and it is not available to delivery to germany 🙁

so i went on with some help of friends and found

| dimensions | voltage | power | current | resistance (guess) | power@ 6V | power@ 9V | power@ 12V | power@ 24V | link |

|---|---|---|---|---|---|---|---|---|---|

| 70mm x 15mm | 12V | 70W | 5,8A | 2,06R | 17W | 39W | 70W | 280W | HALJIA 12V 70W Wired MCH Metal Ceramic Heating Plate Heating Element 70mm x 15mm |

| 70mm x 15mm | 24V | 110W | 4,6A | 5,2R | 7W | 15,6W | 27W | 110W | Haljia 24V 110W Wired MCH Metal Ceramic Heating Plate Heating Element 70mm x 15mm |

| 40mm x 40mm | 12V | 48W | 4A | 3R | 12W | 27W | 24W | 192W | Haljia 12 V48 W Wire MCH Metal Ceramic Heating Plate Heating Element 40 mm x 40 mm |

| 40mm x 40mm | 24V | 96W | 4 | 6R | 24W | 13,5W | 48W | 96W | Haljia 24 V96 W WIRED MCH Metal Ceramic Heating Plate Heating Element 40 mm x 40 mm |

to get an idea of how much power i actually need i had a look at the small commercial IR-Heaters and Hot-Plates –

they all have about 800W:

180mm * 235mm = 42300 mm² = 423 cm²

a = 60mm * 60mm = 3600 mm² = 48 cm (1x4)

b = 60mm * 80mm = 4800 mm² = 48 cm (2x2)

c = 60mm * 90mm = 5400 mm² = 54 cm² (1x6)

d = 60mm * 120mm = 7200 mm² = 72 cm² (1x8)

e = 120mm * 60mm = 7200 mm² = 72 cm² (2x4)

f = 120mm * 90mm = 10800 mm² = 108 cm² (2x6)

g = 120mm * 120mm = 14400 mm² = 144 cm² (2x8)

423 cm² == 800W

1 cm² == x

x = 800W * 1cm² / 423cm² = 1,89W

a = 800W * 36cm² / 423cm² = ~68W (1x4)

b = 800W * 48cm² / 423cm² = ~91W (2x2)

c = 800W * 54cm² / 423cm² = ~102W (1x6)

d = 800W * 72cm² / 423cm² = ~136W (1x8)

e = 800W * 72cm² / 423cm² = ~136W (2x4)

f = 800W * 108cm² / 423cm² = ~204W (2x6)

g = 800W * 144cm² / 423cm² = ~272W (2x8)

30x40mm: ~23W/module

60x15mm: ~17W/modulethen i calculated the resistance of the found element to check on what wattage i can do at what voltages:

U = R*I

P = U*I

→ P = U*(U/R)(i added these *guesses* in the table above)

So I decided to go with the 70x15mm 24V model.

and will update here if i found how this works out..

and for the first test setup i will go with the concept

12V→ 27W / module

so definitive more then enough..

as power supply i will use a MeanWell GST280A48-C6P

(reichelt) with an fitting connector (reichelt)

to get a 5V for the controller i will go with a recom R-78HB50-05 (VIN: 9-72V)

and for switching the power to the heating elements i will use IRLB4030PBF – MOSFET N-LogL 100V 180A 370W 0,0043R TO220AB

and to drive this a BC 550C as mentioned in this nice article:

Schalten und Steuern mit Transistoren III – Mit MOSFETs höhere Ströme schalten

for temperature measurement i use a Adafruit Universal Thermocouple Amplifier MAX31856 Breakout with an Thermocouple Type-K Glass Braid Insulated – K

and have the plan to use a Melexis IR thermometer

i have ordered a MLX90614ESF-BAA-000-TU

i hope that with this i can precisely track the surface temperature..

so when all the parts arrive i can go on.. with building.

for the Controller i plan to write it in CircuitPython and run it on an adafruit (maybe ItsyBitsyM4) PyBadge –

for now i just want to use the arduino serial plotter or similar with an second CDC-device enabled to log the progress and the flash-drive function of CircuitPython for a text-file with the temperature-profile.

i have written a request in the adafruit CircuitPython forum if there are any PID controller things out there…